Home

/

Masking Tape

/

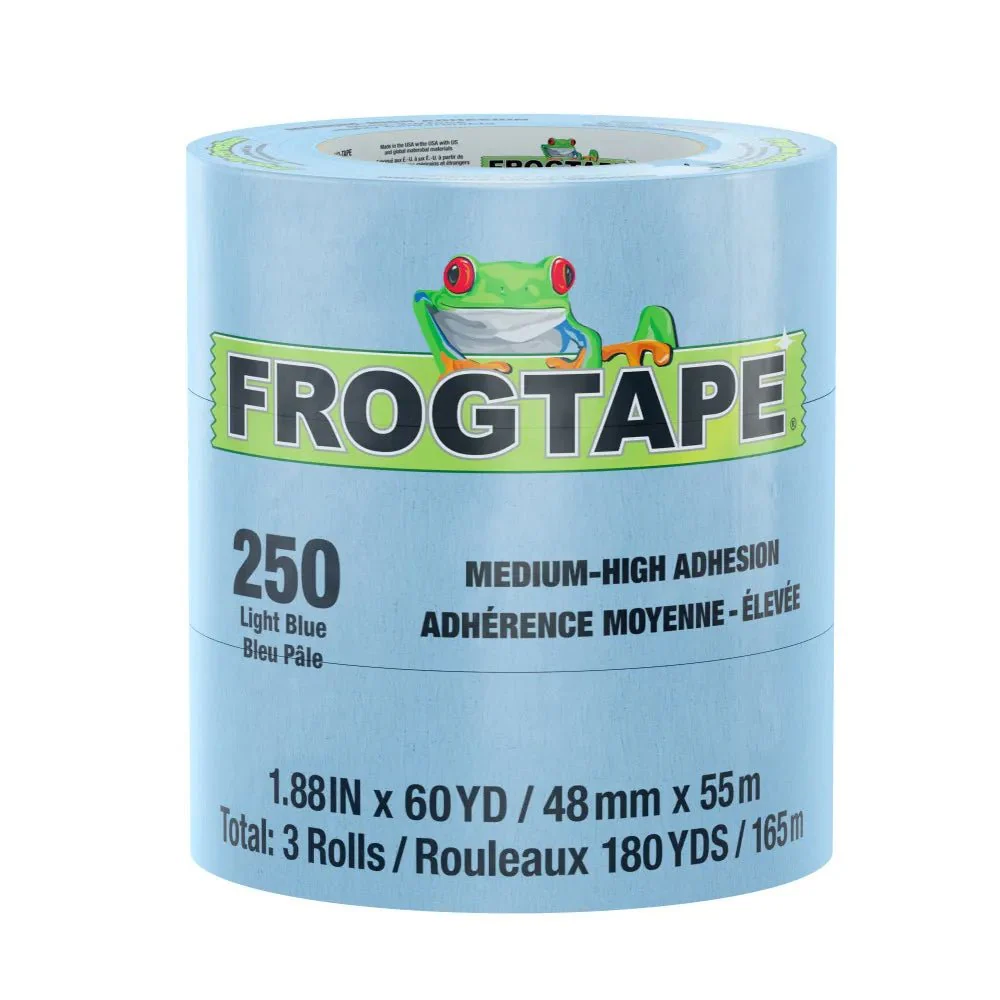

Frogtape® 250 Light Blue Performance Grade Moderate Temperature, Medium-High Adhesion Masking Tape

Frogtape® 250 Light Blue Performance Grade Moderate Temperature, Medium-High Adhesion Masking Tape

Quantity

-

Detail

Performance grade, medium-high adhesion masking tape for use in moderate temperatures in the transportation and metal fabrication industries.

For use in temperatures up to 250 F (for up to 30 minutes), FrogTape® 250 Light Blue is a user-friendly masking solution that delivers consistent paint lines, clean removal and conformability in a range of industrial applications and environments.

Features & Applications

- Prep for Perfection®

- Excellent adhesion to metal, rubber, plastic, anodized aluminum, chrome and fiberglass

- Resistant to water, salt water, various solvents and abrasives

- Compatible with gel coats, multi-part epoxy topcoats, and antifouling bottom paints for marine applications, as well as solvent based and water-born, aqueous paints and coatings for automotive

- Resistant to water, various solvents and gel coats

- Residue-free removal

- Temperature-resistant up to 250 F (for up to 30 minutes)

Markets

- Transportation - General Transportation

- Transportation - Marine

- Converting - Paper Tape

- Industrial MRO - Performance Masking

Construction

Backing: Fine Structured Crepe (FSC)Adhesive: Rubber-based adhesive

Liner: NA

Properties & Technical Data

Product Nomenclature: CP 250

Physical and performance characteristics shown above are obtained from tests recommended by PSTC, ASTM, government agencies or Shurtape Technologies, LLC, Quality Assurance and Technical Service departments and do not represent a guarantee of product performance. Individual rolls may vary slightly from these averages. The user should determine whether the product is fit for a particular purpose and is suitable for the user’s method of application before use.Property Standard Metric Adhesion to Stainless Steel 32.5 oz/in width 3.56 N/10 mm Elongation 10% 10% Service Temperature Range 40 F to 250 F 4 C to 121 C Tensile 24 lbs/in width 42 N/10mm Thickness 6.4 mils 0.16 mm Downloads

Sizes & Colors

Colors Available:

Lengths Available: 60 yds

Widths Available: 0.47 in, 0.70 in, 0.94 in, 1.41 in, 1.88 in, 2.83 in

Sizes and colors disclaimer: Lead times may apply. Please contact Shurtape customer service for information related to stock and non-stock sizes and colors.

Storage & Usage Conditions

Tape should be stored in its original packaging in a cool, dry area away from direct sunlight and should be used within 12 months of date of shipment. Surfaces to which tape is applied should be clean, dry and free of grease, oil or other contaminants.Applicable Standards

ASTM D 6123/D 6123M-97 (2012), Type I -

Customer ReviewsNo comments